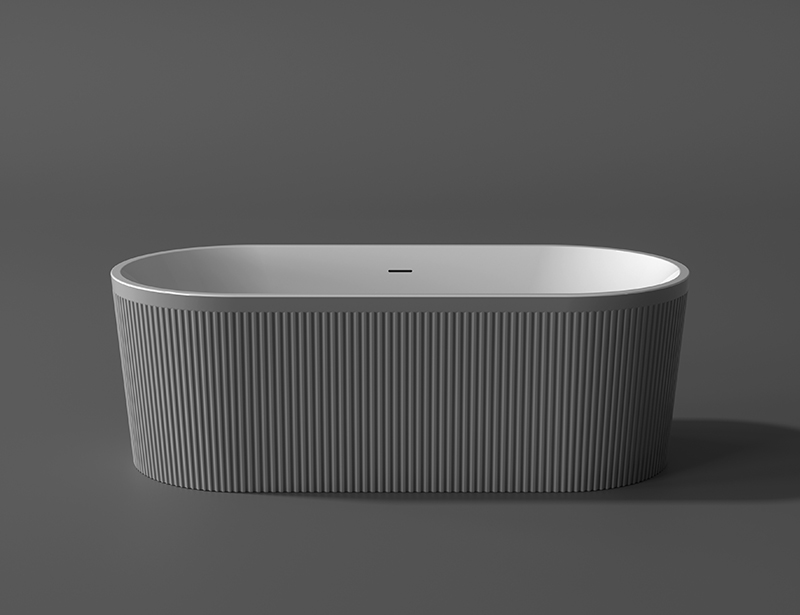

A024 150 160cm MAVAW Whirlpool Massage Bathtub

Model:A024 Dimension:1600X1000X600mm 1500X900X600m...

The mainstream hardware materials of the shower room are basically divided into three types: copper alloy, aluminum alloy and stainless steel.

Most of the copper materials in the shower room are in the form of hinges, which is the so-called flat door. Copper alloy has good corrosion resistance, wear resistance, high hardness, and is not easy to scratch.

Copper is divided into cast copper and forged copper. Casting is to melt the metal and then flow into a cavity with a specific shape, and form a specific shape after solidification; forging is to heat the metal, but it is still solid, and then place it on a platform or a mold of a specific shape, using an air hammer Such tools are forged into specific shapes. The manufacturing process of cast copper is simple, it can be produced in one piece or in batches, and the price is relatively low; but because of the manufacturing principle, there will inevitably be fine pores, and the compactness is far less than that of forged copper. Forging can refine the metal grains and has higher strength than castings, but the manufacturing cost of the mold is very high, and the price will be several times higher than that of cast copper. Moreover, in order to enhance the corrosion resistance of copper alloys, plating must be added, and the degree of adhesion between the plating and the copper alloy is an important indicator of good or bad.

The cost of forging copper itself is high, and the process requirements are high, so it is used in expensive high-end shower rooms.

Aluminum alloy refers to titanium-magnesium alloy in the shower room, and titanium-magnesium alloy can be said to be an enhanced version of aluminum-magnesium alloy. Titanium-magnesium alloys have better corrosion resistance and mechanical properties than aluminum-magnesium alloys, but they are more difficult to process, especially hot working. The strength and toughness of titanium-magnesium alloy is three to four times that of ordinary aluminum alloy. The higher the strength and toughness, the greater the pressure it can withstand. Therefore, considering safety, economy, and aesthetics, most of the sliding doors of professional shower room manufacturers are mainly made of titanium-magnesium alloy.

The purity of aluminum alloy is a very important indicator. In order to save costs, some shower room manufacturers use mostly recycled waste aluminum, which has many trachoma, pinholes, lines on the surface, dark color, soft texture, and is easy to deform or break. Shampoos, body washes, and other cleansing products that have been in contact with the shower room for a long time have more or less acidity and alkalinity. The profiles are difficult to clean and rust over time, which can easily cause the shower room to explode. Good shower room manufacturers, like Furui shower room, strictly control the selection of materials. They use primary aluminum. The primary aluminum has a relatively uniform texture and the surface will be processed in multiple layers. It can be oxidized and colored in multiple colors, the coating is firm, and the color tone is bright. preservative.

Most of the stainless steel in the shower room refers to 304 stainless steel. 304 stainless steel is a grade of stainless steel produced in accordance with the American ASTM standard. Its corrosion resistance is very good. In order to maintain corrosion resistance, 304 stainless steel must contain more than 18% Chromium, more than 8% nickel. There are so-called stainless steel shower rooms launched by many manufacturers. The actual content of chromium and nickel is not up to standard. It is synthesized by mixing 304 stainless steel production waste with other materials. Not only is the corrosion resistance not high, but also the safety is not guaranteed. In view of the production cost of 304 stainless steel, most of the low-priced stainless steel shower rooms fall into this category, and it is not recommended to buy. As we all know, the hardness of stainless steel is very high. According to this characteristic, the shower room made of stainless steel is not easy to deform and is stable for a long time.

Comprehensive comparison (only compare high-quality products of three materials), hardness: forged copper>stainless steel>titanium-magnesium alloy; corrosion resistance: stainless steel>forged copper>titanium-magnesium alloy; ease of forming (will affect the fit with each component ): Titanium-magnesium alloy>forged copper>stainless steel.

Therefore, to buy a shower room, first of all, on the premise that the structure is reasonable, safe, and the materials are qualified, and then choose the material and shape according to personal preferences, in order to find a shower room that suits you.

Model:A024 Dimension:1600X1000X600mm 1500X900X600m...

Model:A1800 80X80X185(cm)90X90X185(cm)100X100X185(...

Model:MV-L691 Dimention:1500X150(mm) Material:Alum...

Model:MV-H308A Dimention:1500X200(mm) Material:Sta...

Model:MV-X167 Dimention:1200X150(mm) Material:Stai...

Model: A2711 80*80*190(cm) 90*90*190(cm) Profile m...

Model: MV020D GREY Dimension: 59.1X29.5X22.8 inch ...

Model: A20P-A 80*190(cm) 90*190(cm) 100*190(cm) 12...